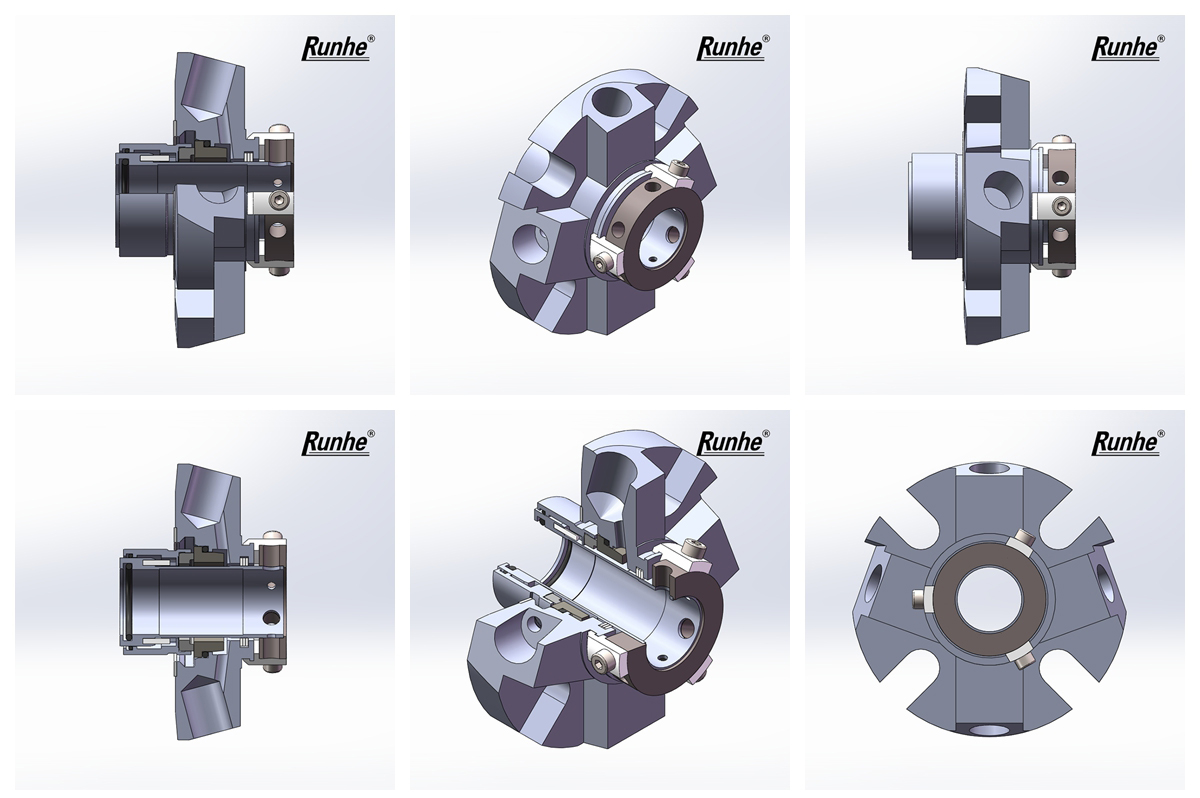

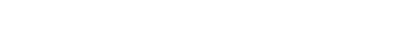

Outside mounted multi-spring mechanical seal, single seal face, rotary type. The installation dimensions conform to ANSI and DIN process pump standards, and conform to the European and American inch standard seal series. The optimized design of the rotary ring seal face is reliable and stable in force, and the material selection range is wide, which is suitable for the fields of power, metallurgy, water treatment, chemical industry, etc.

Selection of seal materials

● Standard configuration: The elastic component is made of corrosion-resistant alloy, the seal face is made of imported high-quality graphite and pressureless sintered SIC etc., and the metal parts are made of Austenitic stainless steel.

● Normal configuration: Adopt general grade materials, the spring is made of chrome-nickel-molybdenum steel, and the seal face is made of resin-impregnated graphite paired with SiC,etc. The metal parts are made of chrome-nickel steel.

Design Features

● Design optimization: The end face design adopts finite element mechanics analysis and is verified by a large number of experiments. The end face contact is ideal when the mechanical seal is working. The low emission requirements of the seal end face can be achieved.

● Set screw positioning: simple and reliable, easy to operate.

● Balanced design: less affected by chamber pressure, suitable for a wide pressure range. No seam allowance positioning, suitable to more pump chamber structures.

Performance Parameters

Size range: 24-100mm (1″-4″)

Pressure: 0-2.5Mpa

Temperature: -30℃-200℃

Speed: ≤25m/s (≤5000rpm)

export@rhseal.com

export@rhseal.com