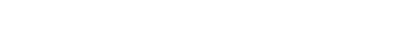

Heat Exchanger:

RHRL series heat exchangers for mechanical seals are mainly used for conveying media with a temperature above 80°C. The function is to cool the media and then send it to the seal chamber, so that the temperature inside the seal chamber drops below 60°C (80°C for oils) to ensure the normal operation of the seal. At the same time, it can be used to cool the seal buffer liquid, etc., to improve the reliability and extend the service life of the mechanical seal.

Function

(1) The surface of the seal friction pair precisely made of different materials at room temperature will deform due to friction heat or excessive temperature of the conveying medium, which reduces the sealing performance. Therefore, according to the different thermal expansion coefficients of the materials, try to reduce their operating temperature.

(2) Generally, if the temperature rises by 10°C, the corrosion rate of the material will double. For seals that rotate at high speed and rub against each other, especially when conveying corrosive media, keeping a low temperature in the sealing cavity is beneficial to prolonging the life of the seal.

(3) As the temperature rises, the viscosity of most seal liquids will decrease, making the lubricity of the liquid worse, accelerating the wear of the seal friction pair, and reducing the life of the seal.

(4) High temperature can accelerate the aging of non-metallic elastic components, such as O-rings, which lose elasticity and thus affect their sealing ability.

(5) For liquids with high saturated vapor pressure, such as high-temperature water, liquid ammonia, liquefied gas, etc., vaporization will occur after the temperature rises, causing dry grinding between the friction pairs and the mechanical seal to fail quickly.

Therefore, the function of the heat exchanger is to select and control the appropriate temperature of the seal chamber under different conditions, so that the mechanical seal is in the optimal temperature environment and ensure its operational reliability and long life.

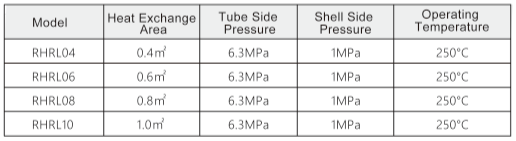

Technical parameters:

export@rhseal.com

export@rhseal.com