Application

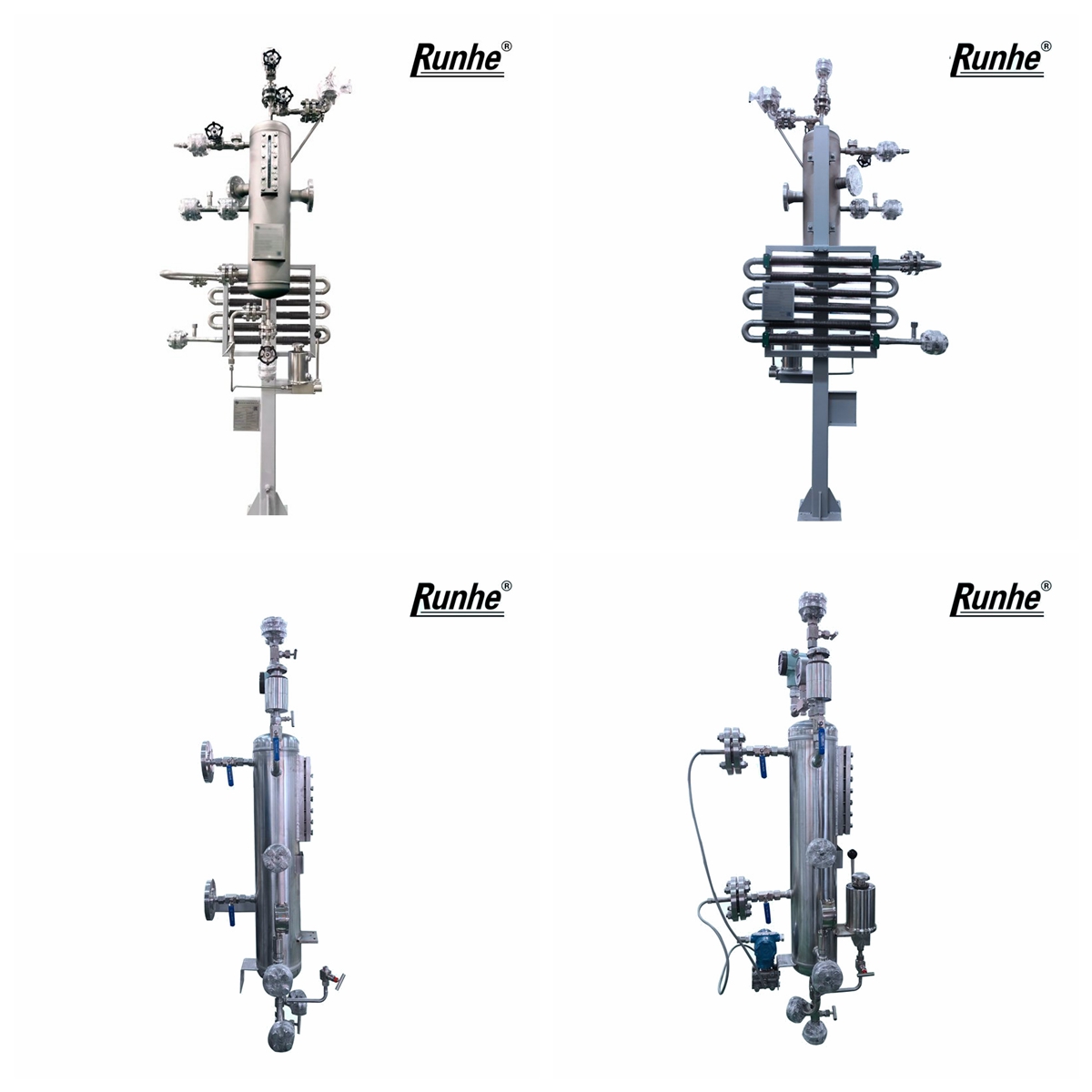

Liquid accumulator can be used as an auxiliary system for multi-stage sealing, but it must be filled with seal liquid (such as buffer liquid, isolation liquid). Heat transfer can be free circulation (thermal siphon) or forced circulation with pumping, and inert gas can be used as the pressure source. The cooling effect is mainly determined by the cooling effect of the auxiliary cooling pipeline. When the pipeline is installed correctly, thermal siphon (self-circulation) will be automatically generated. The cooling effect can be improved by appropriate circulation devices (such as the pumping effect of mechanical seals). Liquid accumulator can only be fully effective when used with other accessories.

PLAN53A Plan

Plan53A Plan is mainly used for tandem mechanical seal or double mechanical seal. The pressurized isolation liquid passes through the liquid accumulator, and the circulation power is provided by the pumping in the cartridge seal. Mainly be used in easily vaporized, flashed hydrocarbons and high-temperature, dangerous, toxic, harmful, easy to crystallize media and other media containing impurities. The isolation liquid pressure in the liquid accumulator must be higher than the medium pressure (0.14-0.41Mpa). If the seal on the medium side leaks, the isolation liquid in the liquid accumulator will enter the sealed medium to prevent the sealed medium from leaking into the atmosphere. The seal leakage can be judged by the liquid level shown by the liquid indicator on the liquid accumulator. The selection of isolation liquid should be consistent with the properties of the process medium. The pressure switch is set to low pressure alarm. The alarm value is usually the pumping medium seal chamber pressure + 0.1Mpa.

export@rhseal.com

export@rhseal.com