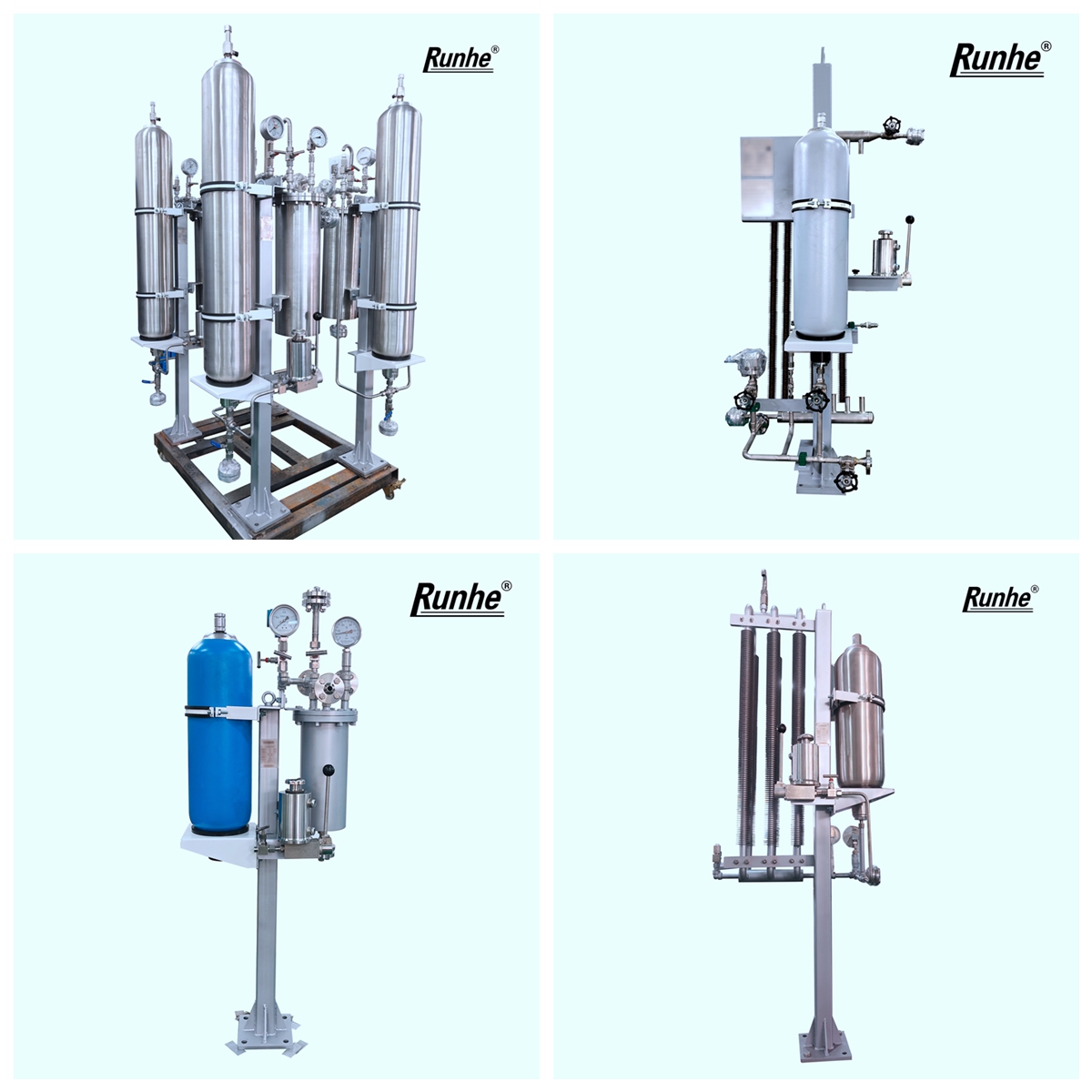

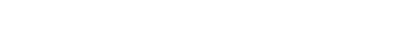

Working principle

This system is mainly composed of coiled tube type heat exchanger, bladder type hydropneumatic accumulator, pressure gauge, temperature gauge and pressure transmitter. The system is mainly used in the seal flushing plan of API682 arrangement mode 3. The coiled tube type heat exchanger is used to cool the friction and stirring heat generated by the secondary seal during operation, and the pumping ring on the seal provides circulation power. The bladder type hydropneumatic accumulator provides stable pressure for the system to ensure the stability of the pressure in the system after the seal leaks, and provides 1.5L of isolation liquid energy storage for the system. If the isolation liquid pressure in the system is lower than (the medium-side seal chamber pressure + 0.1) MPa, the pressure transmitter will generate an alarm signal to remind the operator to add isolation liquid to the system. The isolation liquid can be added through the system's own or mobile manual liquid refill pump. The refilling pressure can be read through the pressure indicator. The general isolation liquid pressure is (the medium-side seal chamber pressure + 0.14~0.41) MPa. (The isolation liquid should be selected according to the characteristics of the process medium, and try to choose a medium with good miscibility with the process medium)

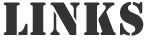

Application

●This Plan is used for double mechanical seals in configuration 3

●High steam pressure and flashing hydrocarbon media

●Dangerous and toxic process media

●Media that are easily heat-conducting

●Dirty media /media with solid particles or easily aggregated media

export@rhseal.com

export@rhseal.com